Guide Version 1

The Guide Version 1 offers integrated control for up to 24 fans, 6 heaters, and 2 pet zones. Through its touch interface, users can select multiple operation modes for fans, heaters, and pets while monitoring real-time temperature, humidity, and CO₂ levels. Features like anomaly prevention, automatic value calculation, and auto-interval mode ensure energy efficiency and operational stability. With centralized management and real-time decision support, it delivers reliable performance for industrial environments.

This system is a high-performance environmental control solution designed for modern poultry automation. Powered by an advanced microcontroller, it continuously monitors temperature, humidity, CO₂, and pressure, automatically managing fans, heaters, lighting, feeding, and alarm systems. The touch-enabled control panel provides intuitive access to all functions, while its modular design, wide output capacity, and sensor flexibility make it suitable for both small-scale farms and large integrated facilities.

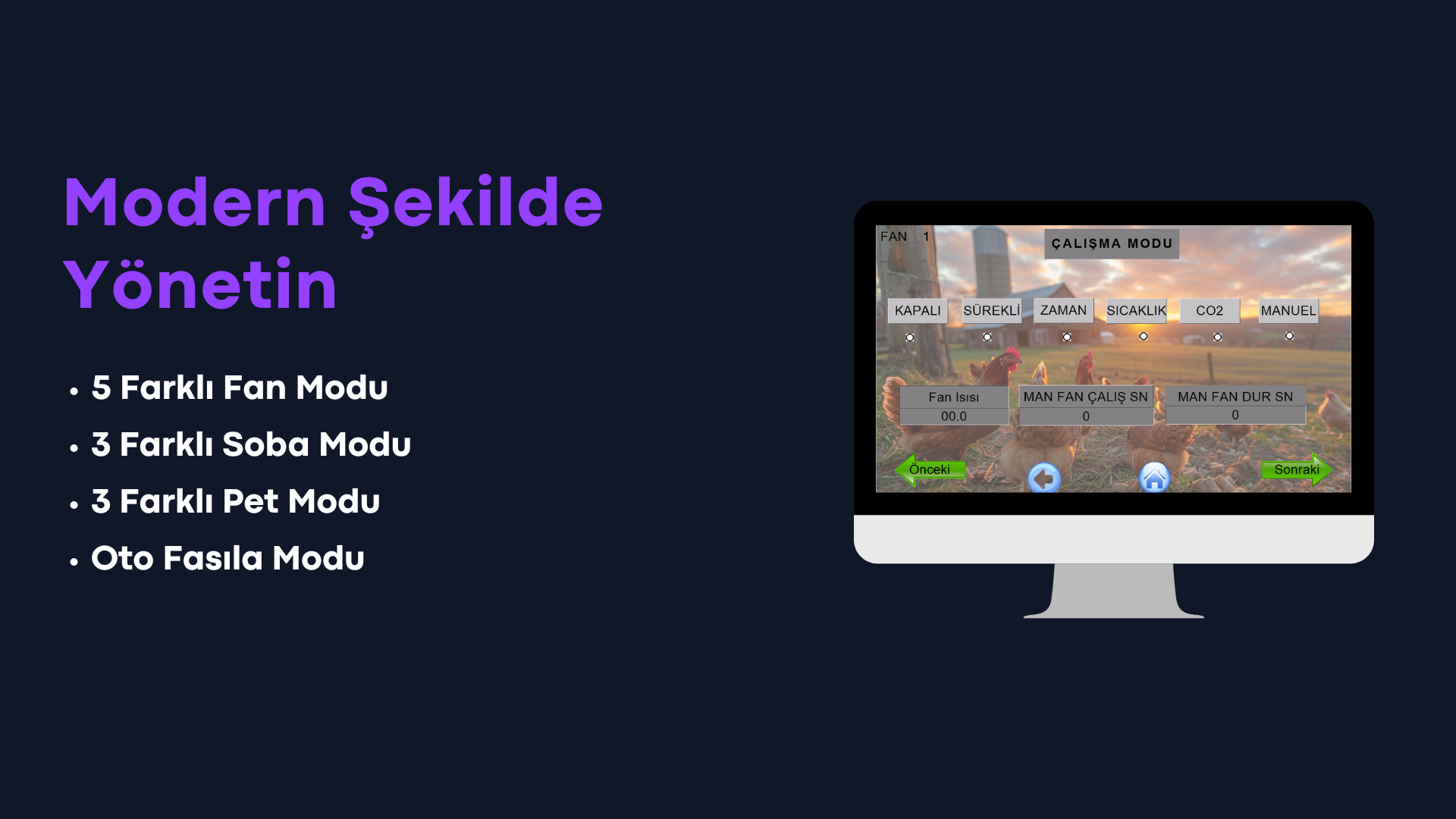

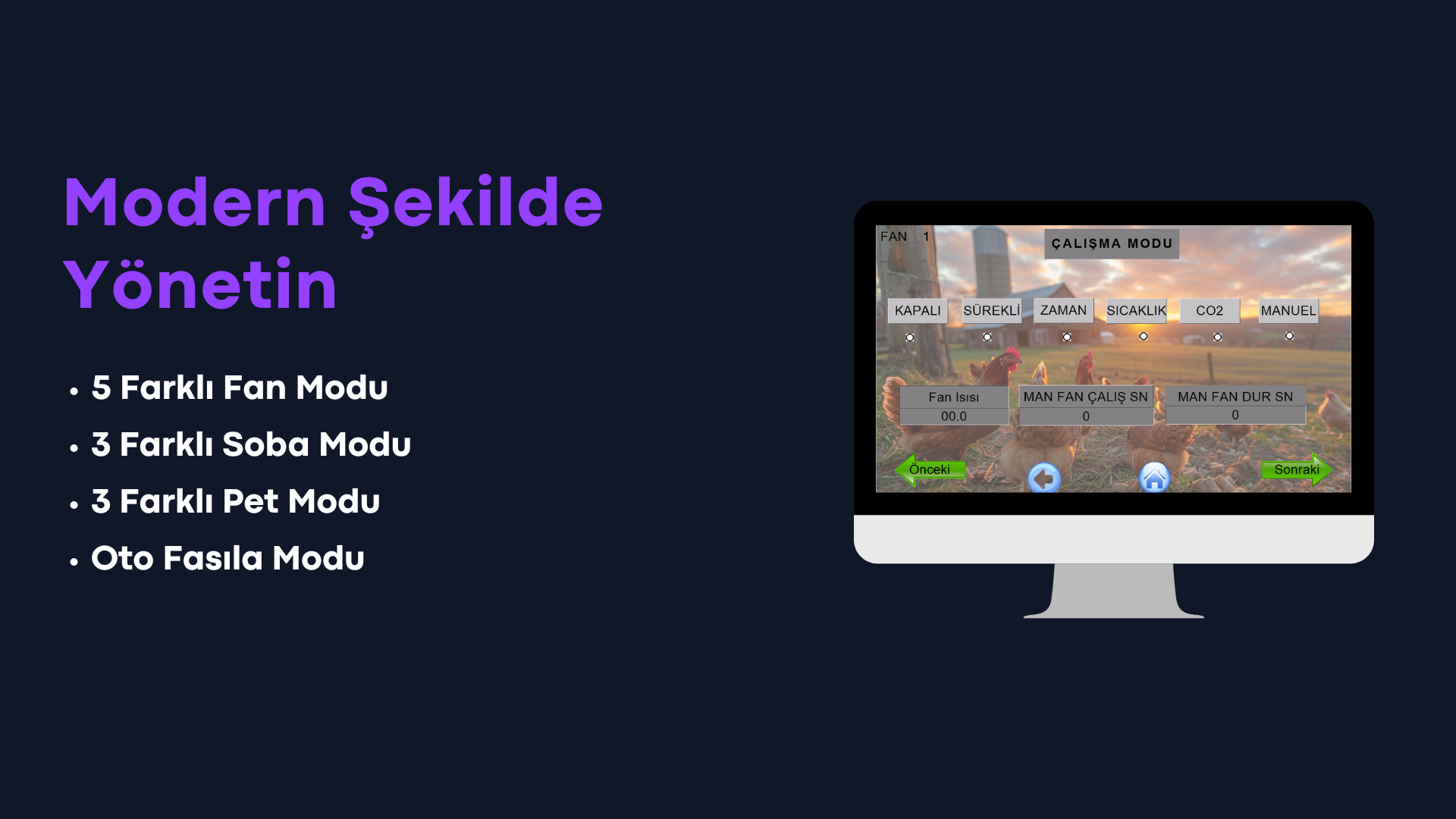

Real-Time Control, Maximum Efficiency

Guide Version 1 is a high–capacity, modular automation controller designed for modern poultry and environmental management systems. It provides centralized control of up to 24 ventilation fans, 6 heaters and 2 pet zones, while also managing lighting, flaps, lids, silos, alarms and feeding units.

With its touch-enabled control panel, operators can easily select different operating modes for fans, heaters and pet areas, monitor live sensor values and adjust setpoints in seconds. Built-in validation prevents invalid data entry, and automatic value calculation reduces configuration errors.

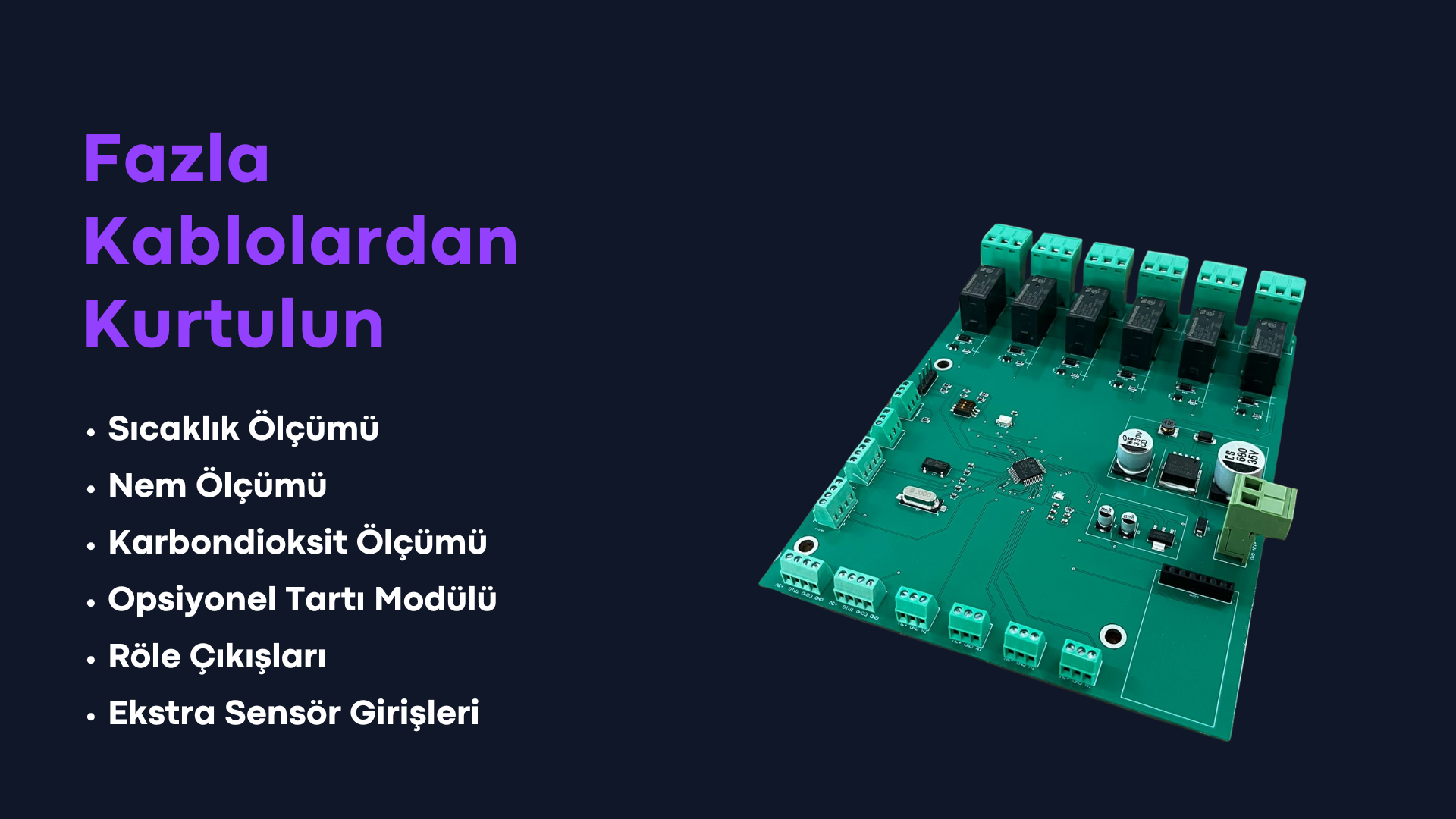

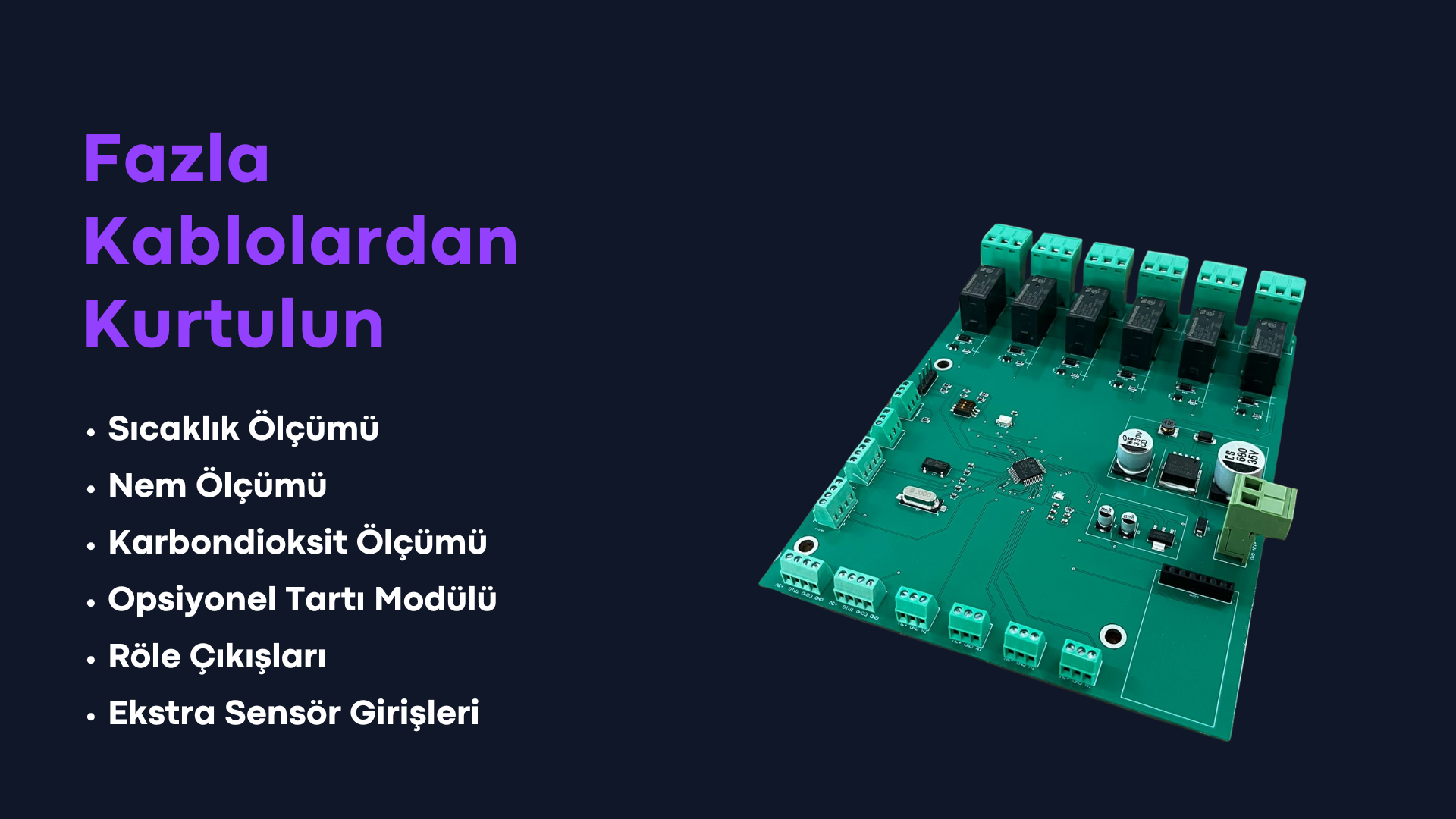

Thanks to its high output capacity, relay outputs, optional weighing module and additional sensor inputs, the system scales from small farms to large integrated facilities. All critical environmental parameters such as temperature, humidity, CO₂ and pressure are tracked in real time, enabling a reliable decision mechanism and an energy-efficient, stable production environment.